Relay socket informtion

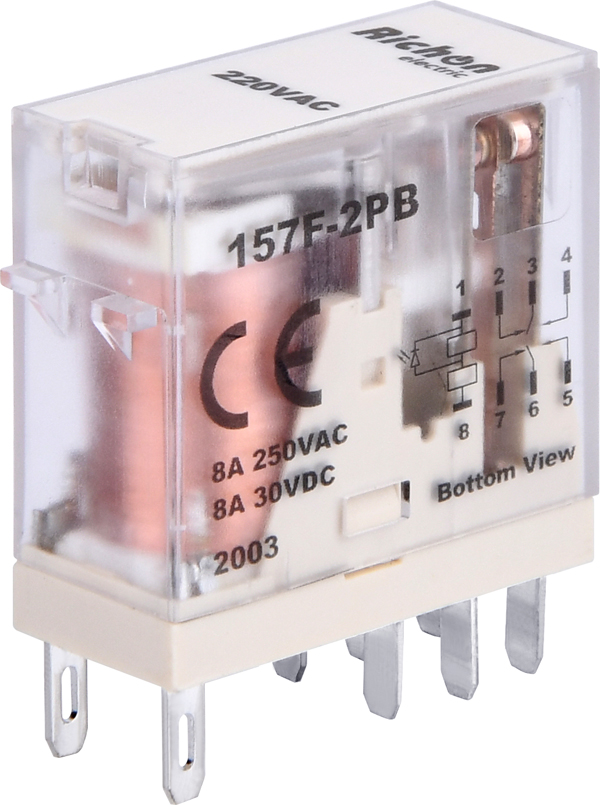

Relay sockets accept electromechanical switches in which the variation of current in one electric circuit controls the flow of electricity in another circuit. Relay sockets are made of metal or composite materials and available in a variety of shapes, sizes, and colors.

Relay sockets differ in terms of terminal type, the number of pins per blade, and socket receptacle style. Terminals are devices that terminate a conductor. They attach to posts, studs or other conductors in order to establish an electrical connection. Typically, these connections are made using screws or by soldering wires or pins. Crimp terminals use the physical compression (deformation) of a contact wire barrel around a conductor to make an electrical and mechanical connection to the conductor. Quick connect / disconnect terminals do not require the use of tools. Most relay sockets use 5, 7, 8, 10, 11, 14, or 16 pins per blade. There are many different socket receptacle styles. Examples include octal or circular sockets, blade or lug sockets, and square or cube sockets. Miniature pin/blade sockets are often called “midgets”. PCB sockets are commonly available.

Specifications

Performance specifications include number of poles, maximum voltage, and maximum current.

- Single-pole (SP) sockets are used with relays that control one line with each throw.

- Double-pole (DP) devices are used with relays that control two lines. Typically, the first line is hot and the second line is neutral.

- Three-pole (TP) sockets accept three pairs of contacts.

- Four-pole devices (4P) receive four pairs of contacts.

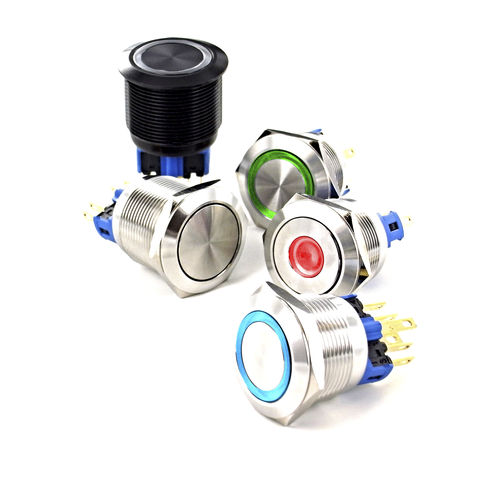

Additional considerations when selecting relay sockets include electrical rating, dielectric strength, insulation resistance, and temperature range. Some products are flame retardant, shatterproof, or designed for demanding applications. Others include electrical or mechanical on/off indicators.

Mounting Styles

There are several mounting styles for relay sockets.

- Through hole technology (THT) mounts components on a printed circuit board (PCB) by inserting component leads through holes in the board and then soldering the leads in place on the opposite side of the board.

- Surface mount technology (SMT) adds components by soldering component leads or terminals to the top surface of the board. Typically, the PCB pad is coated with a paste-like formulation of solder and flux.

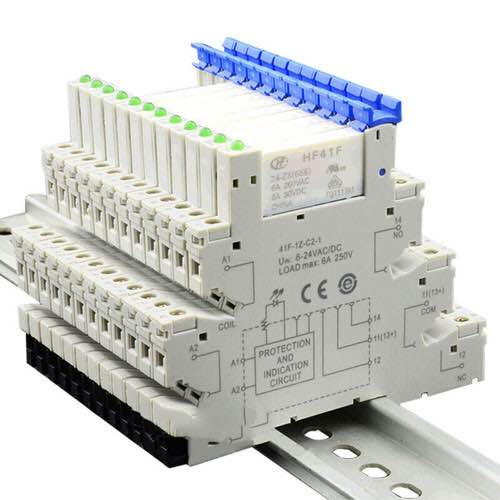

Some relay sockets have mounting holes or are designed for placement within an existing panel or structure. Others mount on a standard DIN rail.